What is there to say about this kit that hasn’t been said before? Probably nothing. But it’s a good one and deserves to be revisited. It’s commonly available and while the accuracy brigade are quick to point out the many flaws (more in the nature of omissions than flaws, really) it builds with typical Tamiya ease straight from the box and the finished model captures the stance and feel of the Abrams.

The M1 Abrams Main Battle Tank is one of a handful of vehicles that seem to have reached a plateau in the development of armour. No new MBT has been designed in America in 33 years, there has been no need because the M1 is largely invulnerable to other tanks, is invariably lethal to them, and after three decades in service is as much an institution as the M16 rifle (which has been around for five). In that time model companies have produced a lot of kits, some better than others, some more buildable than others, but not a single one is 100% accurate, not even Dragon with its patented slide-mould technology. Experts have done the work for the modeller having an attack of AMS (Advanced Modeller Syndrome), you can compare several of the top kits at Vodnik’s site, while a complete list of necessary modifications to accurise any particular kit, assembled by those highly versed in the m1’s anatomy and evolution, can be found here as a downloadable .pdf. On the basis of that .pdf, there are a great many details I overlooked, but I’m not quite so afflicted with AMS that I am up to putting 1:35th scale split-pins and retaining chains on bolts. I can’t build an Abrams without doing at least some superdetailing, and I have done more on this one than previously, around 18 physical additions, plus AM decals and every finishing trick I can think of.

This kit was a retooling of Tamiya’s early-production M1 of 1982, produced about a decade later to reflect vehicles used during Operation Desert Storm in 1991. Basically it is an early generic M1A1, identified as such by the 120mm main gun, revised MRS, main sight, ammo blowout panels and crosswind sensor, smoke grenade stowage boxes, long turret stowage bins, and of course the “bustle rack” for crew gear stowage. The only hull modifications are the NBC environment panel on the port flank (which is missing an important detail) and the cutaway rear panels of the skirt armour.

Assembly is largely based on the 1982 original and the kit falls together as well as it ever did, the only hitch being a tiny mismatch in the upper hull to rear hull joint line, which calls for a bit of finesse and maybe a lick of filler. It’s largely up to you how much superdetailing you want to do, some details are easier than others. Drilling out the solid-moulded towing lugs fore and aft is a no-brainer, and adding missing bolt heads from slivers of styrene rod is another easy one. Relocating the portside grab handle on the forward hull about a scale foot forward to its proper location is another easy one. I also floored the bustle rack with Voyager's photoetched wire mesh part, a distinct improvement on the vinyl mesh supplied in the kit.

Tamiya missed a host of details. The “Z-springs” that tension the hinged forward mudguards are still absent and are easily made from bent spring steel wire. On the NBC panel, a triangular fillet is needed, with a hole drilled to represent the crew heater drain; likewise, the cabin heater intake is missing from the port flank hull and can be made up from a few small pieces of plasticard. On the starboard flank, under the edge of the turret, the bilge pump outlet is missing (only Trumpeter seem to have nailed this detail), and it can be scratched from card and brass tube. A bracket was missed from the hinges of the rear engine bay doors, and some plates and lift lugs too, all easily scratched from cardstock and wire.

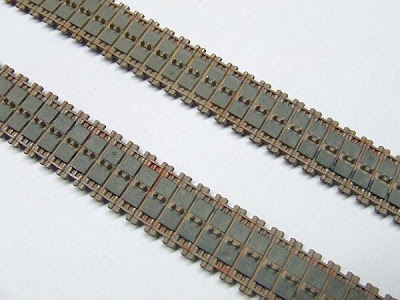

A major criticism is the running gear (above), as the return rollers and idler axle detail are entirely spurious. I had been going to rebuild it all, including the track tensioning piston on each side, but realised that it would be wasted effort. This tank has side skirts and not one item I just mentioned is ever going to be seen, so why bother? The T-156 track is not accurate, the guidehorns should be between links rather than centred on them, but, that said, Tamiya’s T-156 track is the most accuarate in any kit, whether vinyl or styrene (according to Vodnik), and the only replacement set is both very expensive and of the dreaded individual link variety, so I was very happy to overlook this point (as discussed in my previous post).

Assembly was largely trouble-free and the most fiddly and frustrating jobs were late in the process. The barrel of the 7.62mm MG was snapped on the sprue, as was one of the tow cables, and they required very delicate repair with cya, and the antennas are fully scratched. The shorter mast I always make from .015” wire, but the heavier, taller mast I make by scraping .035” rod thinner toward one end, then bending it and CA’ing it into place. The tiedown is usually a plaited bungee chord, and for that I used spandex thread (EZ-line, rather simpler than unpicking elastane thread from a pair of nylons, like I did last time I built an Abrams!), twisted repeatedly, and this took three attempts and a large part of an afternoon. Tying knots with tweezers is my least favourite thing (barring L&L tracks…), but it makes a pretty realistic tie-down. The plastic balls on then ends of the masts are made by dipping the tip repeatedly into paint, and the flexible spring-type mounting at the base of the big mast was done with strips of tape, painted metallic. Trumpeter moulded this part properly, and Academy did so, on other subjects; I doubt their Abrams kits feature them as they were cloned from Tamiya’s.

I used Echelon decals which went on without a hitch (but for one which flicked away from the scissors and vanished) and my only criticism is that they are rather glossy. For that reason I held off on a final round of Mig pigments as I’ll see if I can source a decent clear flat to take the shine off the decals first. One task in pigments that came out very nicely was the burned metal on the transom above the exhaust vents (below), accomplished in seconds with two shades, Vietnam Dust and Black Smoke.

To this day Tamiya provide only tiny scraps of clear plastic for the periscopes, a great let down. I replaced them with styrene inserts and painted them all gold to suggest the prismatic tone of the real deal, but I was not very happy with the way they turned out. I would prefer to look for an aftermarket substitute in future.

Overall paintwork was Testor Model Master Acryl #4812 US Army/Marines Gulf War Sand, a non-FS shade originally mixed from available supplies in-theatre. It went on very well indeed, though my surface prep could have been better, I found myself respraying some spots around the front end when masking took the paint straight off. The tracks, as detailed in a separate post, were done with mainly Tamiya Acrylics.

The finished model looks the part and has enough extra detail to satisfy my desire for accuracy without breaking the bank re my bench hours, or my pocketbook. I could go on, but… Who looks under a tank model to know if the hull bottom is accurate? To be fair, the next Abrams I build will be Trumpeter’s HA and one of the Dragon offerings with all kinds of fine detail, including non-slip texturing moulded in: I ignored the necessity this time as there were some –A1s in Desert Storm which had not received the coating when they went to the Persian Gulf, so I can claim at least some accuracy. I’m happy with the model, my first Gulf War armour, and feel this kit, despite its age and legacy of parts from 1982, captures the design well enough to provide a solid basis for superdetailing, while avoiding the fit and assembly issues reported of at least some of the kits which offer superior detail right out of the box.